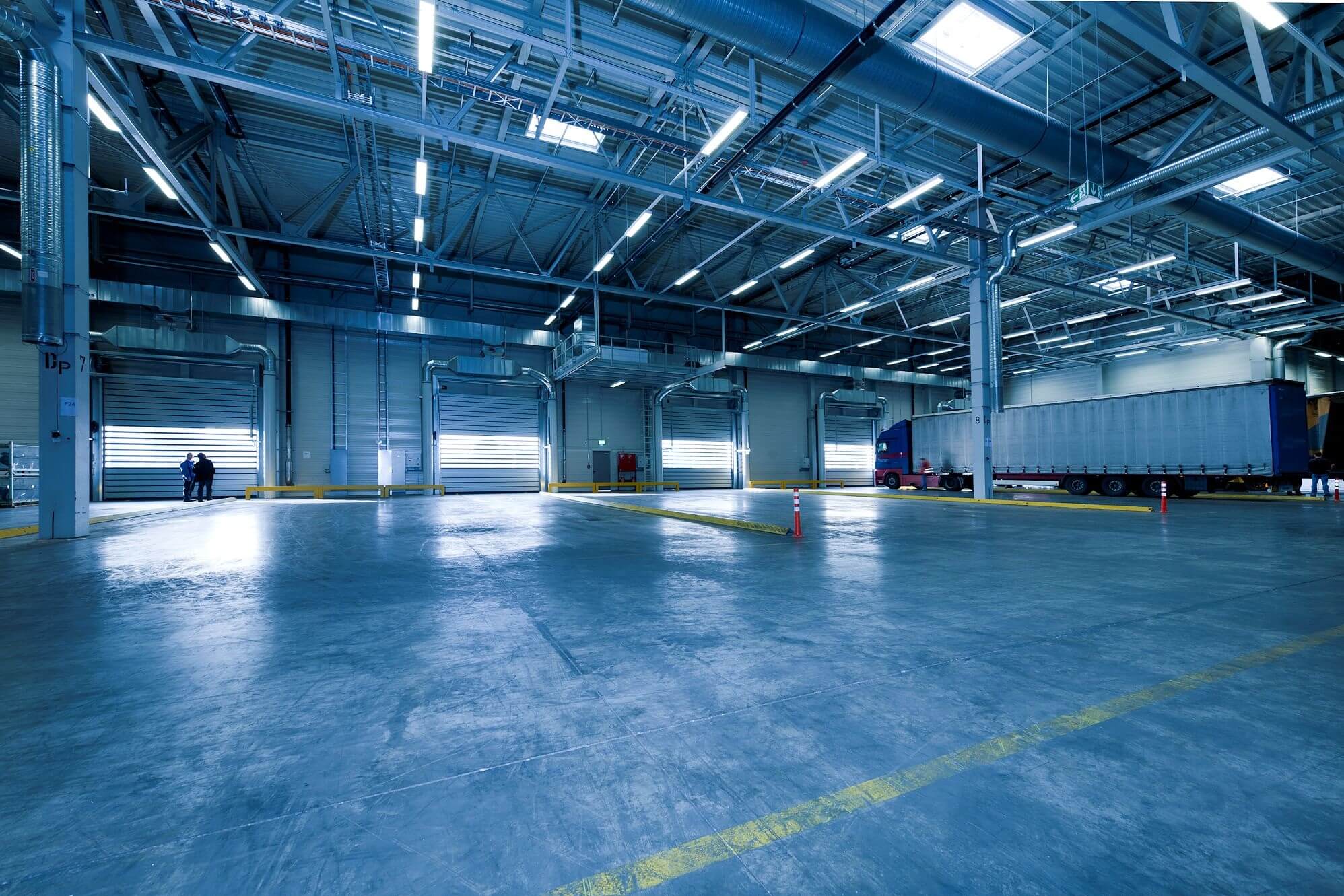

Fluorescent tubes have traditionally been the go-to choice for many commercial premises looking for bright, efficient lighting solutions. LED tubes are designed to be a more reliable, energy efficient alternative, and can save a significant amount on energy costs compared to fluorescent tubes.

What's more, LED tubes retrofit to the majority of existing fluorescent light fittings, making it much simpler to upgrade your old tubes.

Our guide below details the steps to take to install new Crompton Lamps LED T8 tubes only. If you are looking to install another brand of LED tubes, please refer to the manufacturer's instructions.

If you're unsure whether you can do this yourself, we'd advise you to consult a qualified electrician to do the job for you.

Step 1: Remove the old tube

First things first: disconnect the lighting fixture you are replacing from the power supply. Attempting to replace a live tube is likely to result in an electric shock. Once the power is disconnected, remove the old tube from the fitting.

Be sure to handle fluorescent tubes with care. They contain small amounts of mercury, which, while not harmful during normal use, may have an adverse effect on your health if ingested. Place the old tube on a flat surface out of the way.

Step 2: Check and remove the ballast

Fluorescent fixtures all contain ballasts, which will be one of two types: electronic or magnetic. If you're not sure which type of ballast is incorporated in a light fitting, listen for a faint buzzing, or look for a flickering in the light. If you can see or hear this, then it is likely to be a magnetic ballast. Alternatively, take a picture of the light (while it is on) with your smartphone. If the resulting image has black bars or stripes across it, then the light contains a magnetic ballast. If the image is clear, then it is an electronic ballast.

If the fitting contains an electronic ballast, you must remove it to prevent damage to the LED tube. Disconnect the wires from the ballast unit. Remove the unit and connect the loose wires to form a circuit. Ensure the connections are secure and insulated

Depending on the fixture and the tube, you will either need to remove or bypass a magnetic ballast entirely, or just remove the starter (a small unit within the fitting that looks a little like a cylindrical 9-volt battery). Many LED tubes are packaged with an LED starter to make installation easier. However, if you need or wish to bypass the ballast, we'd advise you to consult a professional electrician.

Step 3: Connect the new tube

Carefully connect your new LED tube to the fixture. The tube will have a live connection at one end and a neutral connection at the other. Ensure the wires in the fitment match this. If you connect both live and neutral to one end of the LED tube, you'll cause a short circuit (some fixtures require a single-ended connection, which most LED tubes are capable of, but in these cases the lamp will need to be safely rewired and fitted by a professional).

Step 4: Reconnect the fixture to the power supply

Before activating the lamp, ensure that all steps have been checked thoroughly, and there are no wires left loose. Switch the light on and check that it is operating correctly.

LED tubes should not flicker or buzz. If you do experience either of these, disconnect the light from the power supply again and follow the steps above. If you can't determine the cause of the interference, get in touch with an electrician.

Step 5: Dispose of your old tubes

Due to the small amounts of mercury they contain, fluorescent tubes cannot be included in your normal household/business waste. If disposed of incorrectly, the mercury contained within the tubes could damage the environment, wildlife and even water supplies. Recycling services like Recolight make it easier to dispose of old tubes, allowing you to find locations near you where you can take your old tubes to be recycled.

As LED tubes don't contain mercury, they are easier to dispose of. Before throwing them into the normal waste, though, consider recycling them. They are constructed from materials that most recycling centres should be able to process. Find your nearest recycling site.

UK's #1 Specialist LED Retailer

UK's #1 Specialist LED Retailer

Free Delivery Orders Over £50

Free Delivery Orders Over £50

28 Day Returns Quality Guarantee

28 Day Returns Quality Guarantee